Electro-Static Dissipative Coated Films

IM-ESD 707 Coated PET

Electro-Static Dissipative, Scratch and Abrasion Resistant Film

FEATURES

- Permanent non-humidity dependent ESD surface

- Low Haze

- Chemical and Solvent Resistant

- Abrasion and Scratch Resistant Surface

- Neutral Density Tint

BENEFITS

- Facilitates compliance with IEC 60079-0, CSA 60079-0, ATEX, EN 60601-1-2 standards

- Reduces damage to surface of touch screen, display or cleanroom surfaces

- Protects optical quality of display or touch screen surface

- Print treated back surface for printing/IMD operations

- Environmentally durable

- Easily die cut to fit intended display surface dimensions

PRODUCT APPLICATIONS

IM-ESD 707 coating is designed to provide protection to the surface of touch screens, HM Interfaces, lens systems and softer optical plastic surfaces in abusive or harsh environments and to reduce the probability of electro-static discharge events. IM ESD 707 is available with adhesive on the back side. Users should assure the product meets the specific needs of their application(s).

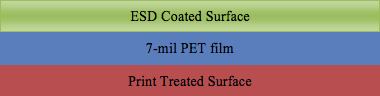

PRODUCT CONSTRUCTION

PRODUCT CONSTRUCTION

- PET .007” (175µm)

- ESD Coating Layer 2.00 to 3.00 micron

- Print Receptive back surface

- Protective Masking both sides

- Available in rolls up to 38” wide or sheeted to specification PHSYSICAL & ELECTRICAL PROPERTIES (IM-ESD 07.7 PET)

- Abrasion Resistance Resists Scratches (#0000 steel wool)

- Pencil Hardness >2H (ASTM D3363)

- Adhesion 5B

- Surface Resistivity 106 to 107 Ω/sq. (ASTM D257)

- Chemical Resistance

– Alcohols

– Ketones

– Most Acids & Bases

OPTICAL PROPERTIES– TYPICAL VALUES

- IM-ESD 07.7 Film (PET) Test Methods

- Refractive Index ~1.65 (ESD layer)

- Visible Light Transmission 80% ASTM D1003

- Haze <1.50% ASTM D1003

Extractable Ionic Content

- Chloride <300ppm

- Nitrate < 200ppm

- Sulfate <200ppm

- Sodium <200ppm

- Ammonium <350ppm

- Potassium <200ppm