Cast and Cure Varnishes

TT101 UV Curable Coating

Cast and Cure Varnish

FEATURES

- Fast cure response

- Excellent feature replication

- Good adhesion to treated PET, PolyPropylene, polycarbonate and paper stock

- Low odor

- Durable surface

BENEFITS

- 100% active composition i.e. no volatile solvents

- Low residual odor in cured coating

- Single component formulation

- Fast cure response

PRODUCT APPLICATIONS

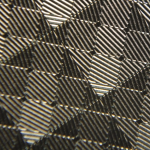

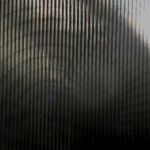

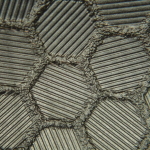

Vampire Optical Coatings’ TT101 Cast and Cure varnish allows replication of decorative effects from embossed films (lenticular, holograms and the like) onto the surface of consumer goods. Users should assure the product meets the specific needs of their application(s).

PRODUCT CONSTRUCTION

Packaging: 1 liter brown HDPE bottles, 5-gallon pails, 55 gallon drums & 330 gallon totes

Solids: 100 % active as shipped

PHSYSICAL & ELECTRICAL PROPERTIES (TT101 Coating)

Adhesion 5B (substrate and treatment specific- should be tested by end user)

Surface Resistivity Not Applicable

Chemical Resistance

- Alcohols

- Ketones

- Most Acids & Bases

Cure Energy <1.0 J/cm2

OPTICAL PROPERTIES– TYPICAL VALUES

TT101 UV cast & coating Test Method

Refractive Index ~1.5 HC Layer

Visible Light Transmission >90% ASTM D1003

Haze <1.00% ASTM D1003

Made in the USA